Examples of industries: plastics processing, moulding, moulding, extrusion, rubber processing, mixers and moulding presses.

Industrial Chillers for Plastics and Rubber

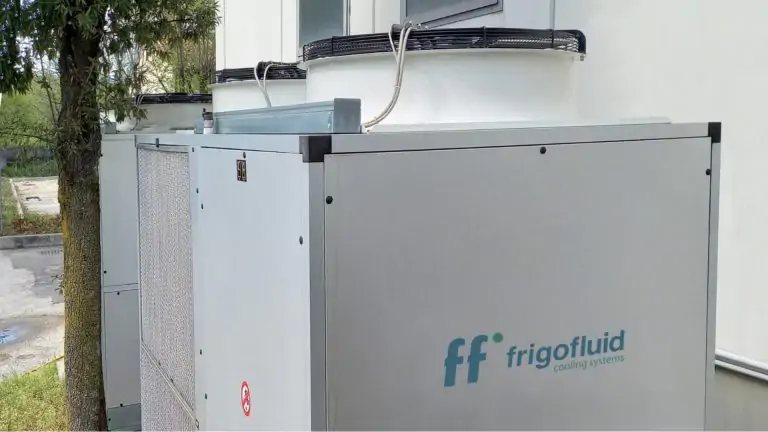

Plastics processing is a heterogeneous sector. Frigofluid’s industrial chillers for plastic and rubber are appreciated in this sector for their reliability and precision. Customers can also request turnkey refrigeration systems complete with refrigeration unit, secondary coolers and other accessories.

Main requirements: heat dissipation with different operating temperatures, hydraulic circuit types and cooling water operating pressures.

Industrial chillers for plastics and rubber: at a glance

Here are some of the activities in plastics processing that require heat dissipation by means of industrial chillers:

- injection or rotation moulding,

- blow moulding,

- extrusion,

- thermoforming.

The utilities requiring refrigeration, cooling or even temperature control are therefore of a different nature depending on the type of department. Therefore, heat management systems can be identified in the following components

- the mould (steel or aluminium),

- the water/oil heat exchanger,

- the calender or cylinder.

The main differences that distinguish the application of refrigeration to the above-mentioned activities therefore concern the operating temperatures, the type of hydraulic circuit and the operating pressures of the cooling water.

Finally, refrigeration for rubber is mainly applied in the closed circuit cooling of moulding presses.

Ask for information

Turnkey Refrigeration Plants

A refrigeration system is more than a single chiller: heat exchangers, hydraulic connections, additional cooling devices also come into play to support your production process.

Air-Cooled Liquid Chillers

Temperature fluido in uscita da +1° a +30° CIn air-cooled liquid chillers, the cooling of the refrigerant gas is ensured by the ambient air itself. Frigofluid offers a wide range of this type of industrial chiller in its catalogue, including a solution with free-cooling.

Water-Cooled Liquid Chillers

Fluid outlet temperatures -8°C to +20° CCooling the refrigerant gas by means of a water exchanger: this is what characterises the water-cooled chillers, which use this feature to ensure high system efficiency. Frigofluid water chillers, with output temperatures down to -8° C, are ideal when air movement is not possible.

Industrial Dry Coolers and Adiabatic Dry Coolers

Industrial dry coolers are a useful solution where fluid outlet temperatures no lower than the external temperature are required. Adiabatic dry coolers are a version of these industrial coolers that can offer outlet fluid temperatures lower than the external temperature.

Industrial Thermoregulation Units

Water control temperatures from +90° to +140° CIndustrial termoregulation units manufactured by Frigofluid are designed to condition moulds and cylinders in various industrial processes. In plastic moulding, process fluids are kept at temperature, thus reducing the use of electrical power for heating and limiting the cooling power spent on cooling by self-stabilisation.

Remanufactured chillers for immediate delivery

Remanufacturing is a 'hot topic' in industrial production, especially in times of resource rationalisation: Frigofluid can supply its customers with remanufactured chillers. A totally sustainable solution.

Some Frigofluid projects

Saving Energy with a Turnkey Refrigeration System

A large plastics processing company needed to renew its refrigeration plant in its entirety. During the summer shutdown and the concomitant production stoppage, we built a turnkey refrigeration plant complete with: chillers, adiabatic coolers, heat exchanger, electrical panels and storage tank.

Read moreManufacturing Brand chooses Frigofluid Turnkey Refrigeration Systems

Chillers, coolers, temperature controllers, accessories and installation services for an Italian designer objects company.

Read moreContinous Saving in Plastic Moulding with Frigofluid Chillers

Frigofluid supplied a chiller with built-in free-cooling to a Veneto-based plastic moulding company as part of the expansion of its production system (addition of new presses). The consultancy covered not only the technical solution, but its incorporation into the plant's entire heating and air-conditioning system.

Read more