Examples of industries: wineries, slaughterhouses, dairies, industrial or craft breweries, beverage companies.

Chillers for Food and Beverage

Chillers for the food and beverage sector must also be able to operate at high temperatures that are peculiar to certain areas of the planet. The preservation of food product properties may also depend on precise temperature control. Finally, energy optimisation is particularly appreciated.

Main requirements: high efficiency, precise temperature control.

Chillers for the food and beverage sector: some examples

Here are some processes from the food and wine industry that use chillers:

- temperature-controlled fermentation;

- must clarification for white wines;

- tartaric precipitation;

- summer air conditioning of cellars, storerooms and any other room, including civil use;

- cooling of cold rooms for meat, dairy, fruit and vegetable storage;

- any cooling application for the agro-food sector.

Turnkey Refrigeration Plants

A refrigeration system is more than a single chiller: heat exchangers, hydraulic connections, additional cooling devices also come into play to support your production process.

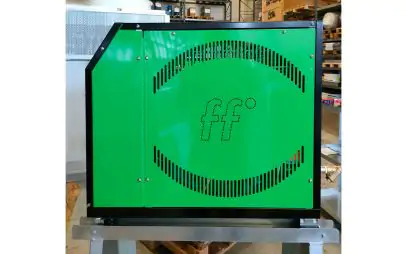

Air-Cooled Liquid Chillers

Temperature fluido in uscita da +1° a +30° CIn air-cooled liquid chillers, the cooling of the refrigerant gas is ensured by the ambient air itself. Frigofluid offers a wide range of this type of industrial chiller in its catalogue, including a solution with free-cooling.

Water-Cooled Liquid Chillers

Fluid outlet temperatures -8°C to +20° CCooling the refrigerant gas by means of a water exchanger: this is what characterises the water-cooled chillers, which use this feature to ensure high system efficiency. Frigofluid water chillers, with output temperatures down to -8° C, are ideal when air movement is not possible.

Industrial Dry Coolers and Adiabatic Dry Coolers

Industrial dry coolers are a useful solution where fluid outlet temperatures no lower than the external temperature are required. Adiabatic dry coolers are a version of these industrial coolers that can offer outlet fluid temperatures lower than the external temperature.

Industrial Thermoregulation Units

Water control temperatures from +90° to +140° CIndustrial termoregulation units manufactured by Frigofluid are designed to condition moulds and cylinders in various industrial processes. In plastic moulding, process fluids are kept at temperature, thus reducing the use of electrical power for heating and limiting the cooling power spent on cooling by self-stabilisation.

Remanufactured chillers for immediate delivery

Remanufacturing is a 'hot topic' in industrial production, especially in times of resource rationalisation: Frigofluid can supply its customers with remanufactured chillers. A totally sustainable solution.

Some Frigofluid projects

Water Chiller and Compressors for Energy Efficiency

Our partner, an Italian energy efficiency contractor, needed to modernise the production processes of a food products company: Frigofluid selected a water chiller and three compressors.

Read moreCustom Chiller for a Machinery Manufacturer

Frigofluid is also available for highly customized chillers: this is what a food industry machinery manufacturer also required for a chiller solution capable of working in outdoor environments and with fluid output at temperatures below 0°C.

Read moreProcess Thermoregulation for a Food Manufacturer in Chile

We have supplied a confectionery manufacturer in Chile with a temperature control unit FT09-110DC-pm: output fluid at 110°C stable over time.

Read more